- Home

-

Biogas Projects

By Size By Gas Utilization By Application

- Biogas Plant Technology

- Service

- Blog

- Resources

- Company

- Contact

Suitable for

Napier Grass

Corn Straw

Bagasse

Lignocellulosic substrate like various agricultural straw.

Technical features: Microbial pretreatment rapidly degrades cellulose, hemicellulose, producing a large amount of VFA.This significantly shortens the retention time in digester and improves substrate utilization efficiency.

Microorganism pretreatment, fast degradation of cellulose, hemicellulose, etc, produces a lot of volatile fatty acids, effectively shorten the hydraulic retention time of digester, improve the utilization rate of materials.

This technology is specially applied in the pretreatment of fiber raw materials. YHR are collaborating with the German company BIONOVA for the application of this technology, and we have obtained a patent in China. It has been successfully applied in some new and renovated biogas projects in Europe. It is a fiber raw material pretreatment technology that has been proved feasible by practical engineering. At present, our company has successfully applied this technology in large scale biogas plant projects across China.

Suitable for

Paddy Straw

Wheat Straw

Raw materials with very high total solid content.

Technical features: Gradient fermentation ensures that the material absorbs water fully within a sufficient HRT, adding efficient decomposition bacteria to promote water absorption and improve decomposition. Reduce the risk of material crusting in the digester.

The lignin content in the straw raw material is related to the maturity of the straw, and the straw raw material in Asia is very mature when harvested, so the lignin content is high. The raw material in Europe is low in maturity and contains whole crop silage.

The lignin content is high and the straw has strong floating power, it is difficult to dissolve in water.

Straw material properties are hard, friction is large, and it is difficult to dissolve in water, and be degraded by microorganisms.

It is easy to form the floating layer in the digester and clog the system.

For dry straw, in a static state, it will begin to settle for about 3 days.

How to dissolve straw faster?

Adopt an effective pretreatment system, the process of straw dissolution is accelerated and reduces the HRT in the digester

The hydrophilicity of straw was accelerated by adding bactericides and installing agitator in the pretreatment system

1

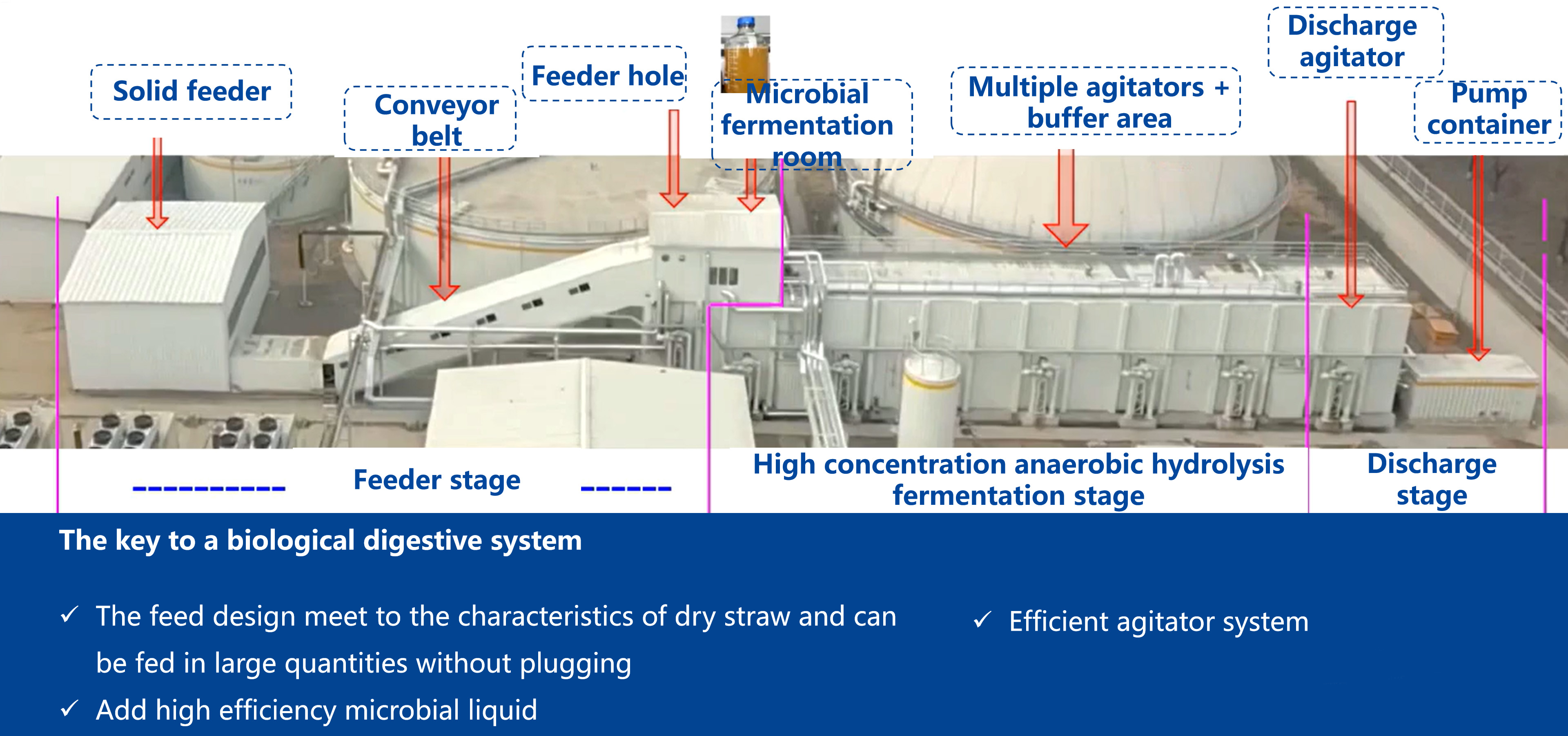

Crushing requirements: Large particle sizes can be applicable.

Achieve large continuous straw feeding, more than 10t/h.

The reactor closes and anaerobic environment, reduce carbon loss and contributes 7-10% of methane production.

The straw is fully dissolve in water and Effectively reduce the risk of scum formation in the digester.

Reduce whole system energy consumption.

Anaerobic system run more stable.

Increase productivity by more than 20%.

Smaller tank volume requirement save cost.

Reduce anaerobic residence time, HRT 23-30d.

Biogas has extensive utilization pathways. It can be used for power generation through gas internal combustion engines, cogeneration, direct industrial and residential heating, as a household cooking energy source in rural or remote areas, or as a fuel. When biogas is upgraded and compressed (forming CBG, Compressed Biogas), it can be used directly in a CNG gas plant to replace conventional compressed natural gas as vehicle fuel, particularly for buses, trucks, and other heavy-duty vehicles. Additionally, it can serve as an industrial fuel, used in boilers and kilns, replacing traditional coal and liquefied petroleum gas (LPG).

In the context of increasing global energy shortages, biogas, as a clean and renewable energy source, particularly in its compressed form—CBG (Compressed Biogas), shows tremendous development potential and broad prospects.

1. Energy Security and Independence

Global energy shortages are becoming increasingly severe, with traditional fossil fuel supplies being unstable and prices fluctuating significantly. CBG, as a renewable energy source, can effectively reduce dependence on imported fossil fuels, enhancing energy security and independence. For countries reliant on energy imports, developing the CBG industry can effectively ensure the stability of energy supplies and strengthen energy autonomy.

2. Environmental Protection and Sustainable Development

The production and utilization of CBG offer significant environmental advantages. Firstly, burning CBG emits almost no carbon dioxide or other greenhouse gases, making it much cleaner compared to traditional fossil fuels. This helps in reducing air pollution and greenhouse gas emissions. Secondly, using agricultural, industrial, and municipal waste to produce biogas can effectively reduce waste accumulation and the environmental issues associated with waste disposal, promoting resource recycling and sustainable development.

3. Economic Benefits and Social Development

The promotion of the CBG industry can bring significant environmental benefits as well as substantial economic and social benefits. Developing the CBG industry can create numerous job opportunities, drive the development of related industrial chains, and promote local economic growth. For example, converting agricultural waste into valuable products can directly increase farmers' income and improve rural economic levels. Agricultural residues such as corn straw, paddy straw, wheat straw, and Napier grass can be used as biogas feedstock, thereby increasing the income of local farmers. Additionally, CBG as a substitute for vehicle and industrial fuels can effectively reduce energy costs and improve economic efficiency.

4. Technological Advancements and Market Potential

With continuous technological advancements, the production and utilization technologies of CBG are becoming increasingly mature, significantly improving production efficiency and economic viability. The application of advanced anaerobic digestion, biogas purification, and compression technologies has gradually reduced the production costs of CBG, enhancing its market competitiveness. Moreover, global policy support for clean energy and increasing market demand further drive the rapid development of the CBG market.

5. Diverse Application Scenarios

CBG has a wide range of applications and diverse utilization pathways. As a vehicle fuel, CBG can replace compressed natural gas (CNG) and be used in buses, trucks, and other heavy-duty vehicles, reducing pollution in urban transportation. In the industrial sector, CBG can serve as a fuel for boilers, kilns, and other equipment, replacing coal and liquefied petroleum gas (LPG), thus achieving cleaner industrial production. Furthermore, CBG can also be used for power generation, heating, and household gas, providing a stable and reliable clean energy source.